Established in 1972, TÜBİTAK Marmara Research Center (MAM) operates at the TÜBİTAK Gebze Campus in Kocaeli. With its R&D and innovation capacity in Energy Technologies, Climate and Life Sciences, Polar Research, and Materials and Process Technologies, it aims to be a global leader in science and technology. With strong infrastructure and internationally recognized management capabilities, MAM is a key player in advanced technology. Adopting a customer-oriented approach, it offers original solutions to public, private, and military institutions through fundamental and applied research, technology transfer, innovation, facility setup, standardization, consultancy, and training.

A device capable of detecting the type and level of chemical warfare agents in the ambient environment with visible/audible alarms indicating the gas group and concentration level on an OLED display.

Submarine Sonar Transducer Element developed nationally and produced with domestic capabilities, for use in Patrol And Anti-submarine Warfare Ships.

Catalytic converting hydrogen gas, which has flammable and explosive properties at ambient temperature, into water vapor and eliminating the hazard. Usage Area: Defense Industry, Battery Rooms References: It is used in Type 209 and Type 214 submarines in inventory of the Turkish Naval Forces Command.It is recycled and remanufactured.

_Tutucu_Kalipatron_2.jpeg)

Carbon dioxide (CO₂) Absorber cartridge provides the removal of CO₂ from the ambient air in indoor environments. Product Properties: •High absorption capacity for Carbon dioxide •Reduction in storage area and weight with high performance •Increasing the term of duty in indoor environments •High recovery efficiency Areas of Usage: •In all indoor environments where life support systems are used: submarines, mines, shelters, military vehicles etc. References: It is used in Type 214 submarines in inventory of the Turkish Naval Forces Command.It can be recycled and remanufactured.

Engine Turbine Blade, used in turboshaft engines and operating under the harshest conditions for engine components, has been produced with national capabilities as a first in Türkiye at Vice Presidency of TÜBİTAK MAM Materials and Process Technologies High Temperature Materials Research, Development and Repair Center of Excellence. Turbine blades, especially the ones for high pressure turbine modules have been produced with directional solidification (DS – ing.) and single crystal casting (SX– ing.) Technologies.

-Uzay-kalifiye-güneş-paneli-geliştirilmesi-4.jpg)

Power subsystem used to meet the energy requirements of satellites. Body mount space-qualified solar panel compatible with all environmental conditions from low earth orbit to lunar orbit Product Properties: • Production of space-qualified solar panels in ISO Class 7 cleanroom • Efficiency measurement of solar cells and panels in accordance with ECSS-E-ST-20-08C Kullanım Alanı: •Earth observation, SAR, and communication satellites

.jpeg)

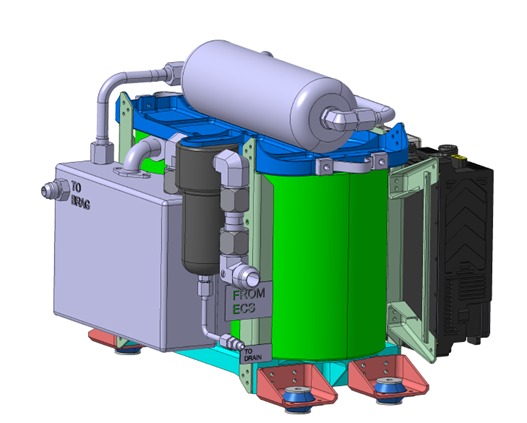

The system, designed for the MMU (National Combat Aircraft) platform, consists of units and components for pressurizing fuel tanks and inerting internal fuel tanks. From the moment the engines are started on the ground, the system is intended to perform all its functions throughout the entire mission profile, including climb and air-to-air refueling operations. The inerting of internal fuel tanks is primarily achieved by creating a flow of Nitrogen Enriched Air (NEA). This is done using an Air Separation Module (ASM) composed of Hollow Fiber Membranes (HFM), which separates oxygen from conditioned Environmental Control System (ECS) air and delivers the NEA flow to the fuel tanks according to the mission profile requirements.

The Life Support System (LSS) is designed to provide advanced physiological protection for the crew of high-speed and high-altitude combat aircraft within the National Combat Aircraft (MMU) platform. The LSS aims to protect the crew from the adverse effects of high-altitude flights and extreme gravitational (G) forces. The Life Support System (LSS) is designed to fulfill three main functions: • Providing altitude protection for the aircrew • Protecting the aircraft crew from the effects of G-forces • Supplying breathable and ventilating/anti-fogging gas of acceptable quality to the aircrew

The chemical protection tests of CBRN protective masks used in military and civilian fields, as well as masks that provide protection against Toxic Industrial Chemicals, are conducted by the TÜBİTAK MAM CBRN Defense Technologies Research Group in accordance with the following standards: • US TOP 08-2-109_Simulant Agent Resistance Test Manikin (SMARTMAN) Testing of Protective Mask Systems • AEP-71_Fit and Protection Testing Methods for Negative-Pressure Respirators • AEP 73_Combined Operational Characteristics- Technical Specifications; and Evaluation; Tests and Criteria for Protective Masks • NIOSH_CET-APRS-STP-0350_ Negative Pressure Air Purifying Respirator (APR) • NIOSH_NPPTL-STP-CBRN-PAPR-0550_Powered Air Purifying Respirator (PAPR)

In the CBRN Protective Suit Integrity Test System, the suit ensemble (suit, mask, gloves, boot covers) is tested as a whole against CWA simulant vapor (e.g., Methyl Salicylate) in accordance with TOP 10-2-022 and ASTM F2588. The suit’s sealing performance, including at junction points, is assessed using simulant vapor introduced into the test chamber. Simulant collected in sorbent tubes on the moving mannequin is analyzed by TD-GC-MS to calculate the protection factor. The total leakage must remain below harmful levels. The test identifies product compliance, weak points, and manufacturing defects, providing valuable data for product improvement.

.jpeg)

Passive RIS: In the context of 5G communication systems, reconfigurable (adaptive) intelligent surfaces are being developed to enable 5G connectivity in areas outside the coverage range of civilian communication networks. Static RIS: In the context of 5G communication systems, static reflective intelligent surfaces are being developed to enable 5G connectivity in areas outside the coverage range of civilian communication networks. Transparent RIS: In the context of 5G communication systems, transparent intelligent surfaces are being developed to enhance the RF transparency of office building windows.

• It is aimed to develop, produce, and conduct verification and acceptance tests of a thin and lightweight ballistic glass system for armored vehicle platforms, which is not currently produced domestically and is subject to export license. • A domestically developed ion-strengthened laminated glass with high ballistic resistance is suitable for land, air, and naval platforms, without compromising vehicle speed, maneuverability, or visibility, and ensures the safety of personnel and equipment. • The design verification process has been completed through relevant component and acceptance tests. • The system meets EN 1063 BR7 protection level and is thinner and lighter than its counterparts.